Product description:

NanoTech industry products Dip coating device is a professional Automatic sol-gel separation system to Nanofilm coating and Sol-gel coating and to produce hybrid polymers, inorganic and similar film coating systems for research and quality management.

Dip coating is a well-known and popular one Sol-gel coating method for the formation and shaping of nanofilms for research purposes. Uniform dip-coated nanofilms can be applied to a variety of specimens, such as flat, cylindrical specimens.

This Automatic dip coating machine consists of the latest chip technology combined with a user-friendly programming method and intuitive menu navigation, a large color LCD color display with backlight and optionally with a large color touchscreen display (model NIP-168Touch), comfortable soft-touch controls, robust and ergonomic design with reliable quality .

Furthermore, this ensures Dip coating system a vibration-free precision movement for the application of nanofilms and sol-gel coatings.

This Automatic dip coating machine is available in two different configurations, with rechargeable Li-Ion battery to ensure maximum flexibility with application possibilities as well Desktop dip coating system as well as in a vacuum box or in a climate chamber with temperature resistance for use as a desktop dip coating device as well as for dip coating in cold rooms, laboratory ovens, climate chambers, vacuum chambers and much more.

This dip coating equipment is manufactured in accordance with international technical guidelines and recognized testing standards.

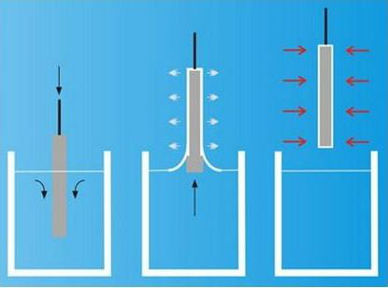

Dip coating occurs in six main stages:

Dip coating level 1 – immersion: The sample body is immersed in the gel completely vibration-free and at a pre-programmed speed.

Dip coating level 2 – retention period: The sample remains in the pre-programmed location, immersed in the solution, for the pre-programmed time.

Dip coating level 3 – Start: The test specimen was immersed accordingly and remained in the solution. The sample body is now lifted out of the gel completely vibration-free and at a pre-programmed speed.

Dip Coating Level 4 – Gelling: The nanofilm forms on the surface of the sample while the sample slowly moves upwards towards the pre-programmed end position. The upward movement takes place completely vibration-free according to the pre-programmed parameters.

Dip Coating Level 5 – Drying: Excessive solution dries and drips from the specimen during upward movement.

Dip Coating Step 6 – Evaporation: The solvent evaporates from the solution and the nanofilm forms.

During the continuous implementation of the dip coating, the above-mentioned stages are carried out chronologically. The built-in microcomputer allows user-friendly programming of the dip coating counter along with the dip coating parameters for user-friendly and fully automatic dip coating and sol-gel coating.

Dip coating is a method of nanofilm coating. Sample specimens are immersed in a solution and, after a defined immersion time, are lifted out of the solution under defined conditions, e.g. speed, temperature, atmospheric influences.

This precision sol-gel coating system is ideal both as a desktop system and as a dip coating device in a vacuum box, laboratory oven or climatic chamber (model QPI-168 (Touch)) and can be used for dip coating of simple as well as complex specimens.

This professional dip coating equipment is manufactured in accordance with international technical guidelines and testing standards.

Sol Gel Coating Machine – Applications:

Dip coating is a well-known and popular one Sol-gel coating method for the formation and shaping of nanofilms for research purposes. Uniform dip-coated nanofilms can be applied to a variety of specimens, including flat wafers, cylindrical solids, and many more.

Dip coating system – special features:

- The latest microcomputer technology for comfortable and user-friendly programming combined with completely vibration-free movement technology and mechanics

- Highest precision: 1µm/min

- User-friendly programming of the immersion speed in the range of 0-500mm/min.

- User-friendly programming of the lifting speed in the range of 0-500mm/min.

- User-friendly programming of the immersion depth (e.g.: 0 mm or a size between 0 mm – 300 mm)

- User-friendly programming of the pull-up speed

- User-friendly programming of the lifting height (e.g.: 300 mm or a size between 0 mm – 300 mm)

- User-friendly programming of the immersion time

- User-friendly programming of the immersion counter (program the number of immersion processes (1 – 9999 times)

- Completely vibration-free immersion and lifting of the test specimen

- Optionally large LCD color display or large color touchscreen display, comfortable and easy to read with backlight

- Powerful Li-Ion battery with up to 2.5 hours of wireless operation

- Custom lifting heights available (please specify when ordering)

- Custom specimen holders available (please specify when ordering)

Automatic Dip coating system - Specifications:

| Model | NIP-168 |

|---|---|

| Latest chip technology | Yes |

| Large color LCD display | Yes |

| Comfortable snap fasteners | Yes |

| Programmable immersion speed | 0,000 - 600,000 mm/min,Display resolution: 0.001 mm/min |

| Programmable lifting speed | 0,000 - 600,000 mm/min |

| Programmable diving distance | 0,000 - 40,000 cm programmable |

| Programmable pull-up speed | 0.0010 - 380 mm/min |

| Programmable immersion period | 1 - 3000s, display resolution: 1 s |

| Programmable immersion counter | 1 - 9999 |

| Standard sample holder included | Yes |

| Sample holders manufactured according to customer requirements are available as an option | Yes |

| User-friendly application | Yes |

| Intuitive menu navigation | Yes |

| User-friendly sample holder | Yes |

| Vibration-free precision mechanics | Yes |

| Operating voltage | 220VAC 50Hz |

| Latest computer technology | Yes |

| Ergonomic design & reliable quality | Yes |

Sol Gel Deposition Device – Scope of delivery:

- Automatic dip coating machine

- Rich accessories

- Carefully professionally calibrated

- Quality certificate

- Calibration certificate

- operation manual

- Extended technical customer service

- Extended Warranty

Get more information about this product now. One of our experts will be happy to contact you with further and helpful information.